Ensure high-quality production

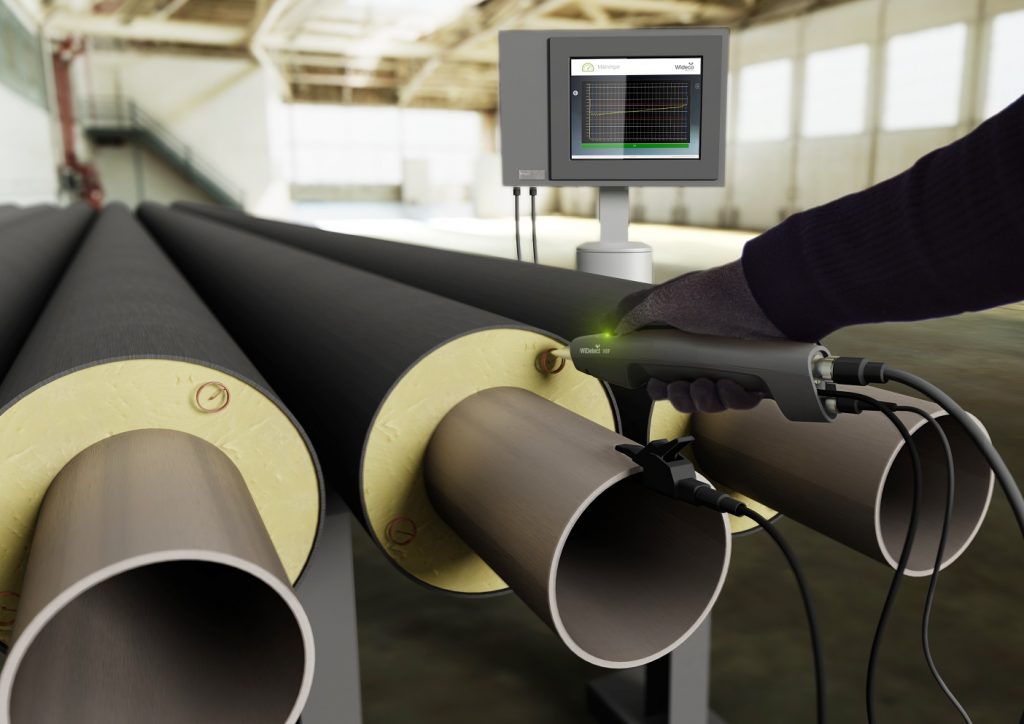

The WiDetect X6F quality system will do the job for you.

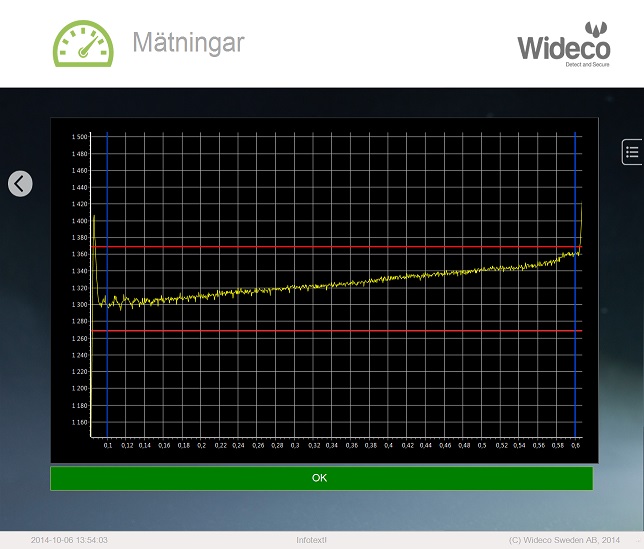

WiDetect X6F is a quality measurement system that makes it easy for you as an operator to accurately measure the various types of pipeline alarm wire system during production work, follow up and secure the production from problems with the alarm wire system. The system gives you a quality check during production and will secure deliveries, minimize warranty issues, save money, improves the sustainability and lessens environment impact.

“Rough, easy and effective”

The X6F makes it easy

We have studied for many years how the production at a district heating pipe factory works. And especially how the staff handles and works with the various steps in producing district heating pipes. We have conducted several user tests and interviews with staff working on the production floor. After this, we have designed and developed several different prototypes on handles to test the alarm wires as simple and fast as possible. We know what is needed and the system can handle the harsh environment that exists in the production of district heating pipes.

The handle is connected to the main system through coaxial cable and the X6F software works extremely fast and accurate. Once you have configurated the system it is easy to start testing your pipes.

Benefits of using the X6F

- Effective maintenance work

- Both stationary and portable

- Superior precision

- Easy software develop for touch screen

- Immediate detection of wire break, short circuit and moisture.

- Immediate detection of crossed alarm wires

- Immediate detection of alarm wires outside limits (distance from media pipe)

- Save and add measuring sites, on-site measurements

- Automatic synchronization to WiDetect cloud (optional)

- Measures on all types on pipes

- For tough environments

- Working temperature device -20 to +50C°

- Remote support available

- Compatible with WiDetect Cloud Solution